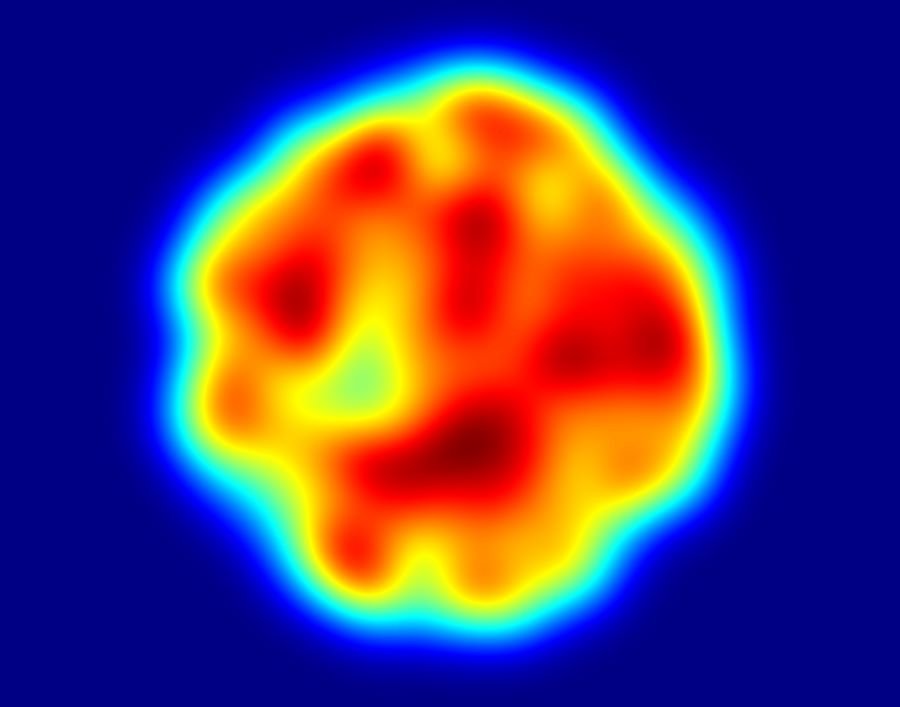

A beam homogeniser is an optical component that provides a uniform irradiance from an otherwise non-uniform input beam. As its name implies, the beam output radiance, or irradiance, is homogenized such that ripples or holes are eliminated from the beam. For many laser applications, this is a necessary operation as any irregularity on the beam can lead to a failure of the laser process in question.

There are many types of beam homogenizers. The simplest, non-shaping homogenizers are gaussian diffusers such as ground glass or opal glass diffusers. These provide a good homogenization of the beam but no shaping to a flat-top profile.

For homogenization combined with shaping, one option is to use a micro-lens array which subdivides, or samples, an incoming beam to multiple lenses, then mix them again at a certain distance. However, these arrays can have ordered artefacts inside the pattern due to the lens pitch.

Another option is to pass the input beam through a long multi-mode fibre. The launched beam at the tip of the fibre will be free of any beam radiance irregularity as the net effect of the fibre is to mix the beam many times along the fibre. This method does require coupling into a long fiber, with the related coupling and propagation losses.

Diffractive Diffuser

A more attractive and compact option is to use a diffractive diffuser. This option is more versatile than the rest as it permits any desired shape for the output beam and shaping by a single thin window. In fact, the final shape of the beam can be rectangular, circular or any other geometrical shape. It can also consist of separate lines or spots or even exhibit a gradient in the irradiance.

The operating principle behind a diffractive diffuser is by controlled mixing of split beams. In order to obtain the desired shape of intensity profile in the far-field or local plane, the incident beam is split by the diffractive diffuser in a semi-random direction.

A diffractive diffuser, and any of the other types of beam homogenizer mentioned above, operates best with low temporal coherence, multi-mode beams with high M2 values. The presence of many incoherent modes in the input beam helps in blurring out the beam non-uniformities without creating interference speckles in the flat-top profile.

The applications for a beam homogenizer are many. Any material processing with lasers will benefit from a constant illumination of the area to be treated. Other applications can be found in medicine, aesthetic, and laser projection systems. Lidar systems, which are becoming more widespread due to the advent of autonomous vehicles, are also a niche application for a large angle laser beam diffusers.